WELLCOME TO VOLTECH

TO YOUR PROSPECTIVE SUPPLIER

CNC-TURNING. CNC-MILLING. presicision by passion.

Services

In our modern production facility in Blankenfelde-Mahlow near Berlin, we focus primarily on rapid prototyping, initial sample production and the production of small and medium series.

We are technologically able to manufacture complex components with tolerances of up to 0.005 mm and to measure them with the help of coordinate measuring machines. We also produce very fine surfaces for your special applications that are absolutely free of burrs, nicks and grease and can have them refined if necessary

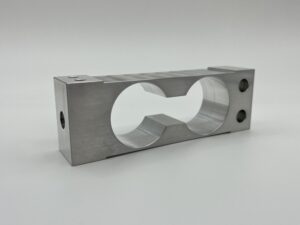

CNC-Milling

In our CNC milling shop we can mill up to 5 axes, even simultaneously.

Processing Areas

3 – 4 Axis

5 Axis

Workpiece Weight

Materials

800 x 400 x 400 mm

200 x 200 x 200 mm

Up to 20 kg

Aluminum, Tempered Steels, Stainless Steel, Technical Plastics.

CNC-Turning

For the production of turned parts, we have universal lathes, multi-axis machines with live tools and automatic lathes at our disposal.

Universal- & Automatic Turning

Chuck Dia

Rod Dia

Lengths

Materials

10 – 40 mm

40 – 200 mm

10 – 250 mm

Stainless Steel, Structural Steels, Free-cutting Steels, Aluminum, Brass, Copper, Technical Plastics.

Products & Customers

We mostly manufacture:

- Housings, valves, special screws and metallic sealing elements for pressure regulators and sensors.

- Components for hydraulic and pneumatic applications.

- Connection elements, closures, distributors, adapters in the field of drinking water supply and medical technology.

- General mechanical components for special machine construction.

- High-Precision parts for military applications.

Our Customers

- Large corporations from the fields of energy, automation and medical technology that need long-term solutions and large quantities.

- Medium-sized special machine builders that we supply with several assemblies but in smaller quantities.

- Machiners from Europe whose capacities are exhausted or rely on external technologies and who need reliable and fast support for their orders.

- Product developers struggling to find suppliers for their prototypes.

Your Benefits

We’re not just a local supplier, we’re a nifty organization.

By clearly distributing the roles in our organization, we ensure excellent synergy.

This synergy allows us great flexibility, more scope for solutions and better calculation options.

By cooperation with us, you will primarily benefit from the following advantages:

Thanks to our central location in Berlin, our customers already benefit from our following services:

- Kanban-Delivery

- Consignment Stock

- Stockpilig

- Just-in-Time

- Marking and labeling according to customer specifications

Delivery in customer’s own or our reusable packaging.

We are not dependent on a single plant and its machine park. We have our A suppliers. Although these have their own core competencies in detail, they still have very similar technologies and standards.

We are therefore able to qualify your long-term, recurring components at two plants. This means that we can cover your peaks in demand not only vertically by using the reserve capacities of the primary plant, but also horizontally, if necessary, by using the capacities of the secondary plant.

At your request and by agreement, we can even set up completely isolated, own production lines for your projects. For this purpose, we procure new systems if necessary, or have existing systems isolated from the rest. This means that only your components are manufactured on these specific machines, which in turn are only operated by specially trained personnel. Also the materials are stored separately.

Stay competitive and flexible with us. We gladly support you!

QUALITY

Quality does not mean what we mean by it, but what the customer expects.

That’s why our quality assurance starts by our customers, rather than in our measuring room.

Understanding Customers

We take our time and communicate about the application of the components, previous problems and look at the whole requirement from the customer’s eyes.

Increasing The Efficiency

By intensive communation we increase the efficiency of programming, selecting the right tools and manufacturing fixtures enormously.

Process Reliability

We ensure absolute reproducibility of the desired quality after every set-up. To achieve this, we build special fixtures, use dedicated tools and much more.

Documentation

We archive material certificates, control plans, measurement reports, etc. as standard so that they can be sent to you at any time upon request.

About Us

VolTech Machined Parts e.K. was founded in 2015 by Dipl.-Bw. (B.A.) Volkan Cinar in Berlin after many years of experience in drive technology and on the international industrial market.

In our first year, our customers were more product developers and small special machine builders

with diverse, short-term and small quantities.

Through this collaboration at the beginning, we have gained immense experience with a wide variety of geometries, tolerances, materials, surfaces and quantities under great time pressure. So we recognized the weak points very early and saw where we are good at and what we had to optimize. That was a self-identification stage for us.

Based on the above experience and the associated further development in terms of capacities, technologies and optimization of our organization, we have since been supplying not only smaller customers, but also predominantly medium-sized special machine manufacturers and large corporations with very sensitive components.

We are an organization. We are a premium service provider. We are VOLTECH.

If you would like to find out more about our services or have current projects,

we look forward to your inquiry.

Contact

Tel. +49 (030) 239 203 20

VolTech Machined Parts e.K.

Goerzallee 299

D-14167, Berlin – Germany